Ceramic Liners

- Can be left grouted or ground to finish to reduce the coefficient of friction

- Highly temperature and chemical resistant

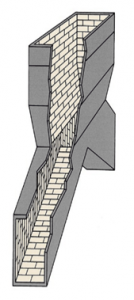

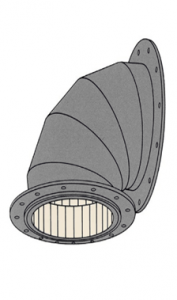

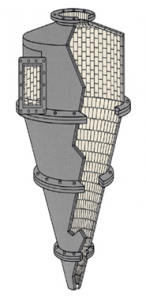

Available for Process Piping, Chutes and Cyclones

VARIETIES:

Trowel On Ceramic

- Most cost-effective option

- Great for lining parts with complex geometry

- Often used to line the section of pipe with lower wear (Tiles would be used to line the high wear areas)

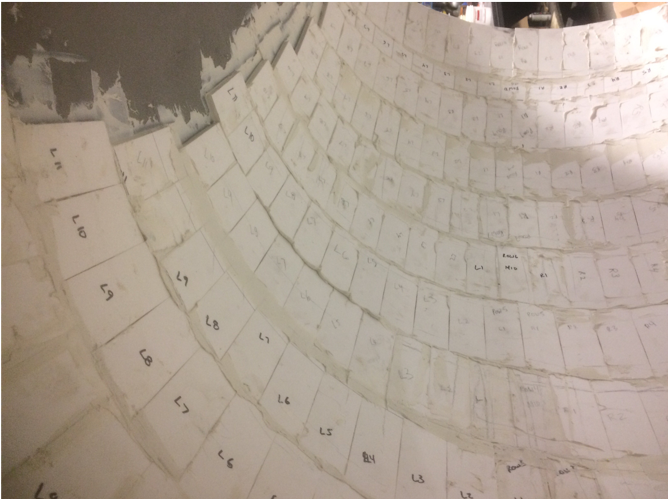

Epoxy Backed Tile

- The industry standard for extreme wear applications

- 2 types: Flat tiles and hex matted tiles

- Flat tiles are used in most applications, hex matted used mainly for conical and cylindrical sections

- Tiles are grouted with high strength epoxy adhesive

- Tiles are custom cut and laid by hand for complex geometries

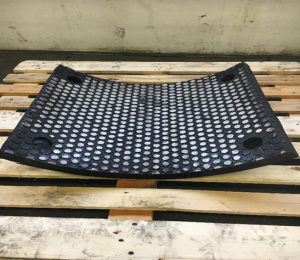

Rubber/Urethane Backed Ceramics

- Specialty option for applications with increased impact

- Ceramic cylinders, hexagonal prisms, or flat tiles are embedded in elastomer

- These liners provide exceptional wear life when facing increased impingement

Other Applications:

Rubber and Urethane backing (Ceramic Pulley Lagging)

Hex Tile Wear Plate in Urethane

Round Dowels of Ceramic in Rubber for Wear Plate.